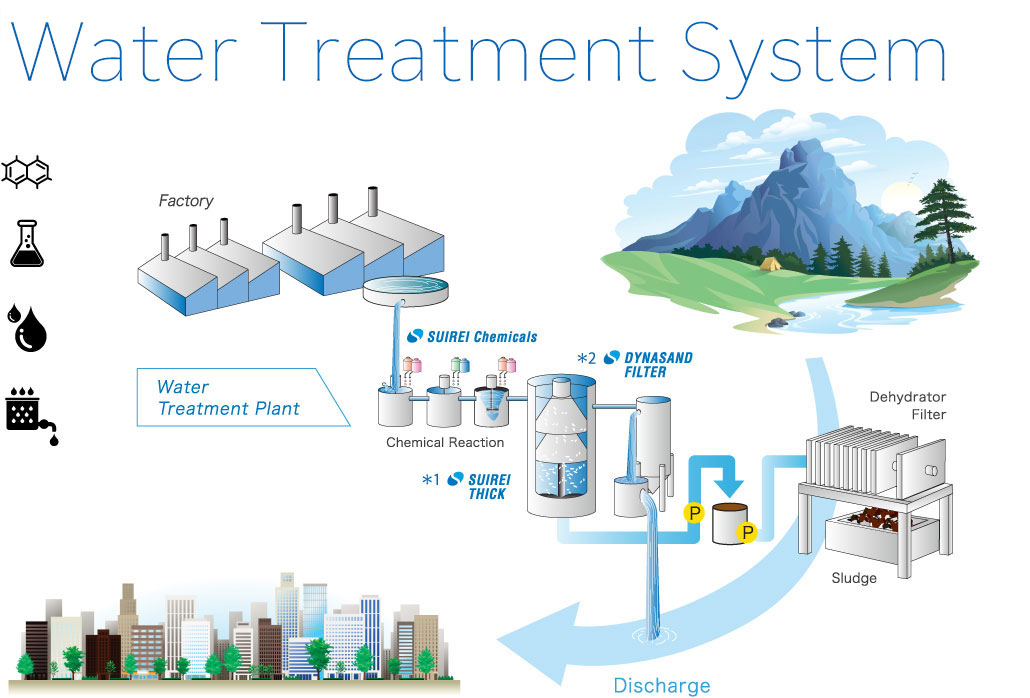

The coagulation sedimentation filtration system is the foundation of water treatment. We offer a tailor-made system according to the unique characteristics of each customer's wastewater. The treatment process begins with the factory wastewater collected in the raw water tank and presented to the reaction tank, where it is injected with a proprietary blend of chelating agents and coagulation aids, which undergo a chemical reaction. Here, oxidation-reduction neutralization/reaction and other treatments are carried out, and appropriate pre-treatment for coagulation is applied to the substances contained in the wastewater.

In the pH adjustment tank, the pH value of the wastewater is adjusted to the alkaline side to further promote the flocculation effect. In the next flocculation tank, the polymer coagulant is added to flocculate the toxic substances.

The wastewater containing toxic substances that have become large flocs is presented to the "SUIREI THICK "*1 sedimentation tank (our patented product), which settles and separates at about three times the speed of ordinary sedimentation tanks, and then returns to clean water after passing through the automatic fluidized sand filter "DYNA SAND FILTER"*2.

We believe that the most important thing is not to stick only to our own products, but to realize our customers' requests through "selection technology" that maximizes the "affinity" of each device and agent.

*1 "SUIREI THICK" high-speed sedimentation tank equipment "Patent No. 1498009"

<3 features> (1) Reduction of residence time, (2) Space saving, (3) Maintenance free

*2 "DYNA SAND FILTER" Upward-flow automatic backwash filter

<2 features> (1) No need to shut down equipment during sand washing (backwashing), (2) No need for equipment for sand washing (backwashing) (tank, pump, etc.)