The flocs settled through the coagulating sedimentation tank are called "metal sludge,” which is harmful to the human body, is also a valuable recyclable metal, a substance that has value in the industrial world.

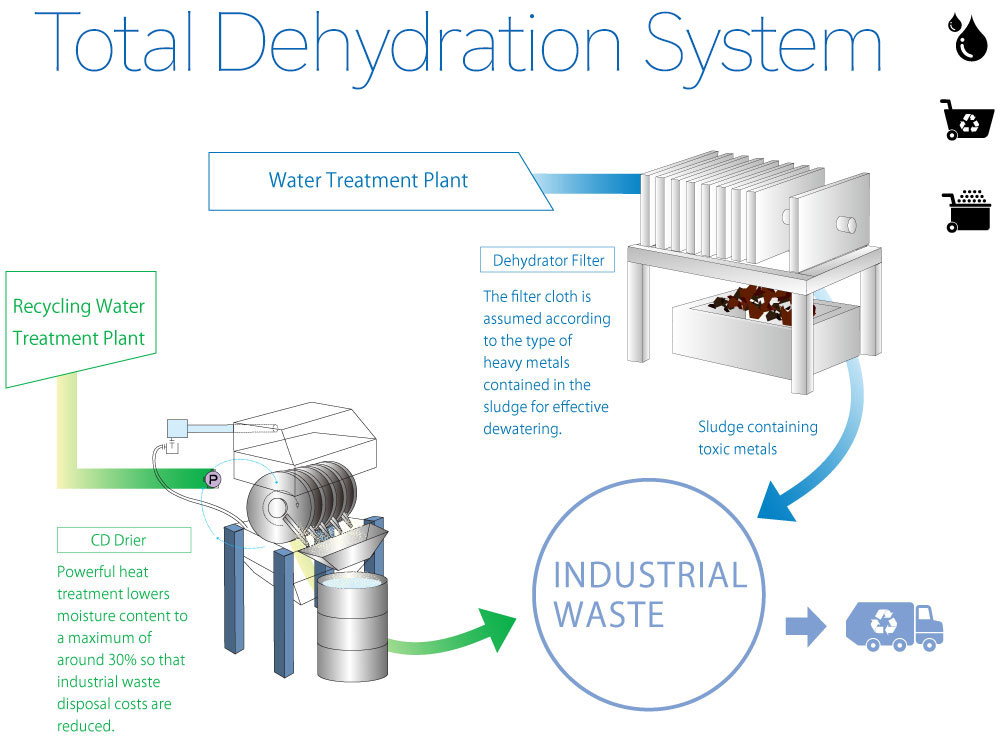

The filter press removes water from the heavy metal sludge and significantly reduces its volume. The average moisture content of the sludge is 99%. By using the filter press, it can be brought down to around 75%. We analyze the properties of various types of sludge and select filter cloths with varying moisture content depending on the material and weave of the filter. By making detailed adjustments related to the press, we dewater heavy metals contained in wastewater efficiently. Depending on the type of wastewater, a diversion-type dewatering system, in which valuable metals such as nickel and copper are dewatered independently, is also an effective measure to reduce industrial waste costs.

Since industrial waste usually has a salvage price based on its weight, the reduction of water content is directly related to cost. In fact, at a plating plant where a water treatment system incorporating a filter press was delivered, the cost of sludge treatment was reduced by half.

The CD dryer, an essential dryer for a complete recycling system, is selected to dry the sludge down to powder form. Since the sludge is subjected to heat treatment rather than pressing, it is now possible to reduce the moisture content to around 30%. (*CD Dryer is a product of Nishimura Iron Works.)