Our salespeople are also consultants. From the initial hearing stage, we do not just take on the role of a listener and communicate to the relevant departments at the head office, but also act as "sales engineers" to propose specific methods to solve the customer's needs and problems. We carefully explain running costs, equipment and chemical options, and their effectiveness from a long-term perspective, and we work to create the "flow sheet" for the water treatment system design while placing emphasis on dialogue.

During the hearing, sales engineers and maintenance technicians who know the details of the site participate, so there is no time lag in the communication between departments. At the same time, the virtual layout on the flowsheet is immediately validated through treatment experiments in our research laboratory. Thus, several plans are created to "balance budget and need" depending on the stage of the project.

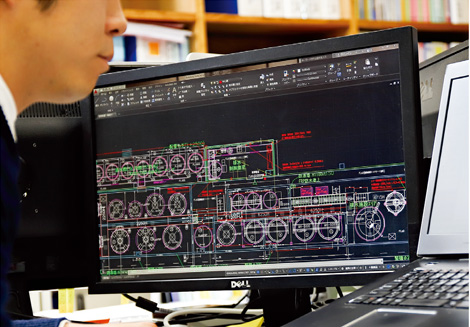

The flowsheet is a "tailor-made design concept" so to speak. The virtual layout of the water treatment system, which was proven to be effective in the hearing stage, is evolved into a specific design in the next stage according to the structure and area of the building requested by the customer. Confirmation of the materials to be used for the electrical control panels and equipment to be custom-made cannot be done only on the virtual layout.

In addition to these hardware adjustments, we also consider the flow lines and ease of use for the customer (administrator) who will be responsible for daily management after the system is in operation. During the facilities management stage, we pay close attention to the latest developments from "basic design" to "actual design" based on our "custom-made design concept."

Field surveys are conducted to evolve the basic design into the actual design. Layout design is our strongest area of expertise. However, in recent years, we have also received an increasing number of requests for "improvement and updating" of systems installed by other companies. In this case, an essential point is the compatibility between the system already installed and in operation and the new equipment or improvements to be added.

Field surveys are conducted to evolve the basic design into the actual design. Layout design is our strongest area of expertise. However, in recent years, we have also received an increasing number of requests for "improvement and updating" of systems installed by other companies. In this case, an essential point is the compatibility between the system already installed and in operation and the new equipment or improvements to be added.

Once the site survey is completed, the PE Design Section begins the specific selection process while pursuing "complete safety," "balance between budget and need," and "ease of use for the customer." Piping is selected based on the pump and its material, calculated from the wetting characteristics, the lift based on specific gravity, and the pressure of the water being pumped. The optimum torque value of the power motor is calculated, and the sensors to be used in the water tank and for measuring water quality are also determined. As the saying goes, "details reveal the quality of the whole," for our water treatment system, every piece of equipment used, down to the smallest screw, and every combination has its own "meaning and effect" that led to its selection. We create the logic for automatic control of the system down to the selection of the valves that operate the pumping of liquid, and create drawings as equipment that is free from unreasonableness and waste. We are ready to answer all your questions and engage in conversations at the stage of the construction work and approval to begin. After numerous meetings, the design proceeds.

Another important partner is essential to achieve "water treatment systems with affinity." Our pride as a specialized company for half a century is shared by our construction partners, with whom we have built diverse water treatment systems. Our partner companies, including can manufacturing companies that produce tanks, installation companies, piping installation companies, and electrical installation companies, boast a high level of reliability.

The installation of water treatment systems requires the access of numerous heavy machines and meticulous work. We are able to meet deadlines because all of our subcontractors have extensive experience and understand the importance of the water treatment system to the customer. For half a century since our foundation, we and our subcontractors have been preventing accidents from occurring on construction sites.

Once construction is completed carefully and quickly, we begin the commissioning inspection. We operate the pumps one after another starting from the point close to the raw water tank, and check water leakage in the piping, the current value of the power, leakage current, and the direction of rotation.

After that, sales representatives and maintenance technicians join in the actual liquid operation and adjustment phase. While actually receiving a small amount of raw water (factory wastewater) and treating the wastewater, the amount of chemicals injected, etc., is adjusted and repeated until it is in accordance with the design.

During the actual operation and adjustment, a customer briefing is held to answer any questions from the perspective of the customer who will manage the system daily, from fine-tuning the system for ease of use to confirming the conduit.